Our Metal

NZAS HAS ONE OF THE LIGHTEST CARBON FOOTPRINTS PER TONNE OF ALUMINIUM OF A SMELTER ANYWHERE IN THE WORLD

OUR PRODUCT

NZAS is a responsible supplier producing consistently high-quality products with one of the lowest CO2 footprints in the world.

Each year we make more than 330,000 tonnes of the lowest-carbon highest-purity aluminium in the world, emitting just two tonnes of CO2 for every tonne of aluminium – the international average is 13 tonnes.

Having such a light carbon footprint per tonne of aluminium of any smelter anywhere in the world means we can take advantage of international demand for greener, more sustainable, low-carbon metal.

Our RenewAl metal brand is externally certified to have smelting emissions of less than four tonnes of CO2 per tonne of aluminium. This guarantees that the aluminium is made from traceable raw materials and is produced with electricity from low carbon sources, using world-class smelting processes.

We produce a range of value-added products, including speciality billets, high purity ingots, and foundry alloys that are cast from low carbon aluminium.

Where is our aluminium used? Find out more here.

How it's Made

FIND OUT HOW TIWAI MAKES THE PUREST ALUMINIUM IN THE WORLD

WHAT IS ALUMINIUM

Aluminium is a strong, lightweight, flexible, non-corrosive and almost infinitely recyclable metal. Those properties make it a popular metal widely used in the transport, construction, packaging and electrical industries.

It can be rolled, extruded or cast as pure aluminium or aluminium alloys.

Most of our metal is cast to customer requirements – either pure aluminium or aluminium alloys – with about 90% exported to international markets.

Aluminium is a key structural material of the 21st century and will have a significant role to play in a carbon-constrained world. Because of its demand for use in lightweight vehicles, it’s the fastest growing material used in the automotive sector.

Using one kilogram of aluminium to replace steel in a car or light truck can save a net 20 kilograms of CO2 over the life of the vehicle.

Aluminium is the perfect metal to advance humanity in a decarbonised world and NZAS, using renewable energy to smelt it, is perfectly positioned to take advantage of that.

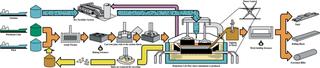

The Process

Innovation and Technology

Yunca Engineering

"For the past 30 years Yunca’s work with NZAS has provided us with a platform to build deep expertise and capability within the Yunca Group. This experience has enabled us to successfully tender and win international contracts from other aluminium smelters including Boyne Smelters, Bell Bay Aluminium, Tomago Aluminium, Dubal and most recently Trimet in Germany.

"The innovative aluminium smelting technology that is proudly engineered in New Zealand can absolutely be attributed to having NZAS on our doorstep. This world-class industrial asset is not only a major benefit for the community, it also supports local businesses to help propel them to the next level."

Karyna Young, CEO, Yunca Group

Callaghan Innovation - New Zealand's innovation agency

"NZAS engaged Callaghan Innovation’s experts on an R&D project to improve how high quality aluminium is manufactured in New Zealand. This process involves electrolysis in hundreds of reduction cells, of which cathode blocks are a major component of the reduction cells structure. Sometimes when a cathode block fails, it can shut down a reduction cell which can lead to significant expense and down time. NZAS were keen to work with our engineers to come up with a solution.

"Callaghan Innovation’s engineers developed a prototype method to screen cathodes for defects before incorporating them into cells. The novel measurement technique was compared to conventional non-destructive testing methods and found to be more effective. This is a great example of successful collaboration between industry and government leading to better innovation outcomes. Our team greatly enjoyed working with the NZAS team on this project."

Robert Holt, Joint Team Leader of Electrical Engineering at Callaghan Innovation